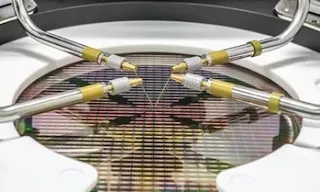

There are several different types of silicon testing

Picture courtesy: https://www.azom.com/

Silicon Design for Test (DFT) is a design methodology used in the development of integrated circuits and silicon chips. The goal of DFT is to make the testing of silicon chips as efficient and effective as possible by designing the chips with testability in mind. This includes the insertion of test circuits, access to internal signals, and other design modifications to make it easier to test the chip's functionality and performance.

DFT techniques can help reduce the cost and time required for testing by allowing designers to perform more tests in a shorter amount of time and by making it easier to identify and isolate any defects.

Some of the key features of DFT include:

Built-in self-test (BIST): BIST circuits are integrated into the chip to perform internal tests and generate test results without the need for external test equipment.

Scan design: Scan design allows for the sequential shifting of test patterns into the chip's internal registers, making it easier to test internal circuits.

Test access mechanisms (TAMs): TAMs provide access to internal signals and nodes, making it easier to perform tests and diagnose any defects.

Reduction in test time: DFT techniques can reduce the test time required for a chip by enabling parallel testing of multiple circuits and by making it possible to perform more tests in a shorter amount of time.

By incorporating DFT techniques into the design of a silicon chip, designers can improve the efficiency and effectiveness of the testing process, which helps to ensure that the chip meets the desired specifications and has a high level of reliability.

Checkout the following:

1. Wafer probe testing: Testing individual devices on a silicon wafer to verify basic functionality and parametric performance.

2. Class testing: The objective of silicon class testing is to verify the functionality and performance of individual components or blocks of the silicon, such as transistors, logic gates, or memory cells.

3. Final testing (End of line Test): Testing packaged chips to verify performance and functionality under full operating conditions.

4. Burn-in testing: High-stress testing of packaged chips to accelerate the detection of infant mortality failures.

5. Qualification testing: Verifying that chips meet required reliability and environmental standards.

6. Characterization testing: Measuring key parameters such as power consumption, speed, and operating temperature range.

7. Production testing: Ongoing testing of packaged chips to monitor performance and identify any potential issues.

8. Silicon sort testing: Separating good devices from bad ones based on their electrical characteristics.

9. Silicon Debug: Debugging the silicon design to find and fix defects.

These tests are performed at various stages of development and manufacturing process and help to ensure that the devices meet required specifications and are functional and reliable.

We will look at each of these specific types in the upcoming posts.

Your comments will be moderated before it appears here.